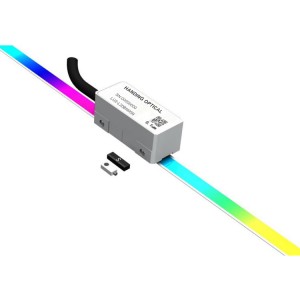

HD20 high-precision optical linear encoders

1. Cov Khoom Muag Khoom

Steel siv grating yog aprecision ntsuas cuab yeejtsim rau linear thiab angular positioning daim ntaub ntawv nyob rau hauv ntau yam lag luam. Nws muab cov kev tsim kho muaj zog nrog cov thev naus laus zis kho qhov muag kom siab precision thiab kev ntseeg tau ntev.

2. Cov yam ntxwv tseem ceeb

High ntsuas qhov tseeb nrog zoo repeatability.

Durable thiab resistant rau hnyav industrial puag ncig.

Txhawb kev koom ua ke nrog automation thiab tswj tshuab.

Kev tsim kho qis rau kev siv nyiaj tsawg

3. Kev qhia tshwj xeeb

Khoom siv:High-lub zog stainless hlau.

Qib raug:± 3 µm / m lossis ± 5 µm / m (nyob ntawm tus qauv).

Ntev Ntev:Txog li 50 meters (customizable raws li yuav tsum tau).

Dav:10 hli mus rau 20 hli (cov qauv tshwj xeeb yuav txawv).

Kev daws teeb meem:Tshaj nroghigh-precision optical sensors(txog 0.01 µm nyob ntawm qhov system configuration).

Kev khiav hauj lwm qhov kub thiab txias:-10 ° C txog 50 ° C.

Cia Temperature Range:-20 ° C txog 70 ° C.

Thermal Expansion Coefficient:10.5 × 10⁻⁶ / ° C.

moos zaus:20 MHz

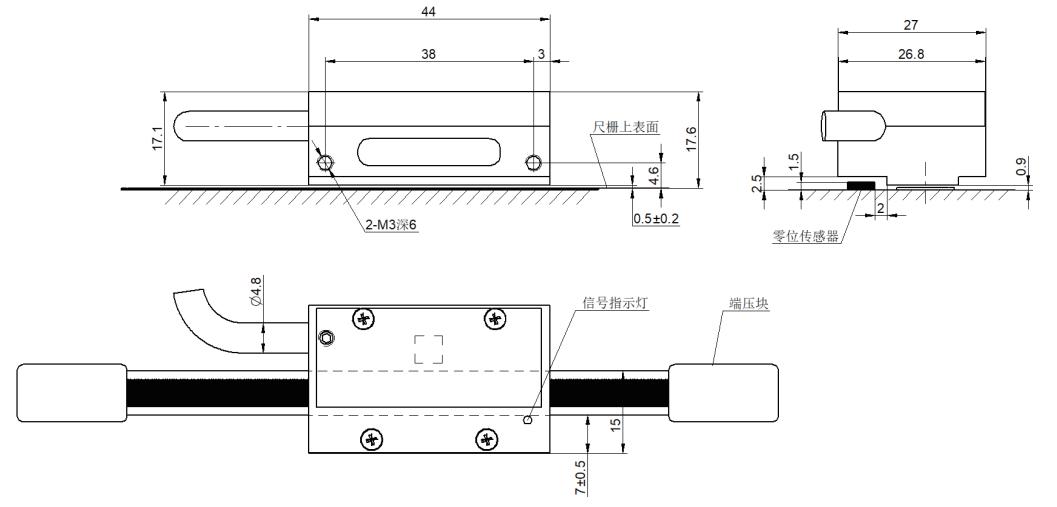

4. Dimension Drawing

Cov hlau siv grating qhov ntev yog cov ncauj lus kom ntxaws hauv kev kos duab, uas qhia txog cov hauv qab no:

Grating lub cev:Ntev sib txawv raws li tus qauv (txog 50 meters); dav yog nruab nrab ntawm 10 mm thiab 20 mm.

Mounting qhov chaw:Precisely ua raws li kev ruaj ntseg thiab ruaj khov installation.

Thickness:Feem ntau 0.2 hli mus rau 0.3 hli, nyob ntawm tus qauv.

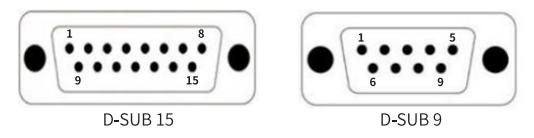

5. D-SUB Connector Paub meej

Pin Configuration:

Pin 1: Fais fab mov (+ 5V)

Pin 2: Av (GND)

Pin 3: Signal A

Pin 4: Signal B

Pin 5: Index Pulse (Z Signal)

Pin 6–9: Tso tseg rau kev cai configurations.

Hom Connector:9-pin D-SUB, txiv neej lossis poj niam nyob ntawm tus qauv tsim.

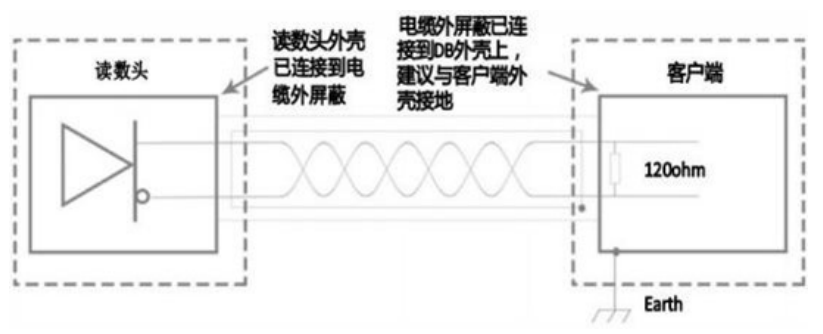

6. Daim duab kab hluav taws xob

Daim duab hluav taws xob xaim hluav taws xob qhia txog kev sib txuas ntawm steel siv grating thiab tus tswj qhov system:

Kev Siv Hluav Taws Xob:Txuas cov kab +5V thiab GND mus rau qhov chaw tswj fais fab.

Cov kab teeb liab:Teeb liab A, Teeb liab B, thiab Index Pulse yuav tsum tau txuas nrog cov khoom siv sib xws ntawm chav tswj.

Tiv thaiv:Xyuas kom cov av zoo ntawm cov ntaub thaiv npog tiv thaiv electromagnetic cuam tshuam.

7. Cov txheej txheem kev teeb tsa

* Xyuas kom lub installation nto huv si, tiaj tus, thiab tsis muaj khib nyiab.

* Siv cov kev pom zoo mounting brackets thiab cov cuab yeej sib dhos rau qhov tseeb qhov chaw.

* Teem lub grating nrog lub ntsuas axis, kom tsis txhob twists lossis khoov.

* Tsis txhob kis cov kab mob xws li roj lossis dej thaum lub sijhawm teeb tsa.

8. Cov lus qhia ua haujlwm

* Paub meej tias kev sib raug zoo thiab calibration ua ntej siv.

* Tsis txhob siv lub zog ntau dhau rau lub grating thaum ua haujlwm.

* Saib xyuas txhua qhov sib txawv hauv kev nyeem ntawv thiab rov ntsuas dua raws li xav tau.

9. Kev tu thiab kev daws teeb meem

Kev tu:

* Ntxuav lub grating nto siv cov ntaub mos mos, tsis muaj lint-dawb thiab cawv-raws li tshuaj ntxuav tes.

* Lub sijhawm kuaj xyuas lub cev puas tsuaj lossis tsis raug.

* Tighten xoob screws los yog hloov cov khoom uas hnav.

Kev daws teeb meem:

* Rau kev ntsuas tsis sib xws, tshawb xyuas qhov sib npaug thiab rov ntsuas dua.

* Xyuas kom cov optical sensors tsis muaj kev cuam tshuam los yog kis kab mob.

* Hu rau kev txhawb nqa yog tias muaj teeb meem tshwm sim.

10. Cov ntawv thov

Cov hlau siv grating feem ntau yog siv hauv:

*CNC machining thiab automation.

* Robotic positioning systems.

* Cov txheej txheem tsim khoom lag luam.

Cov khoom qeb

-

Xov tooj

-

E-mail

-

Whatsapp

whatsapp

-

WeChat

-

Sab saum toj